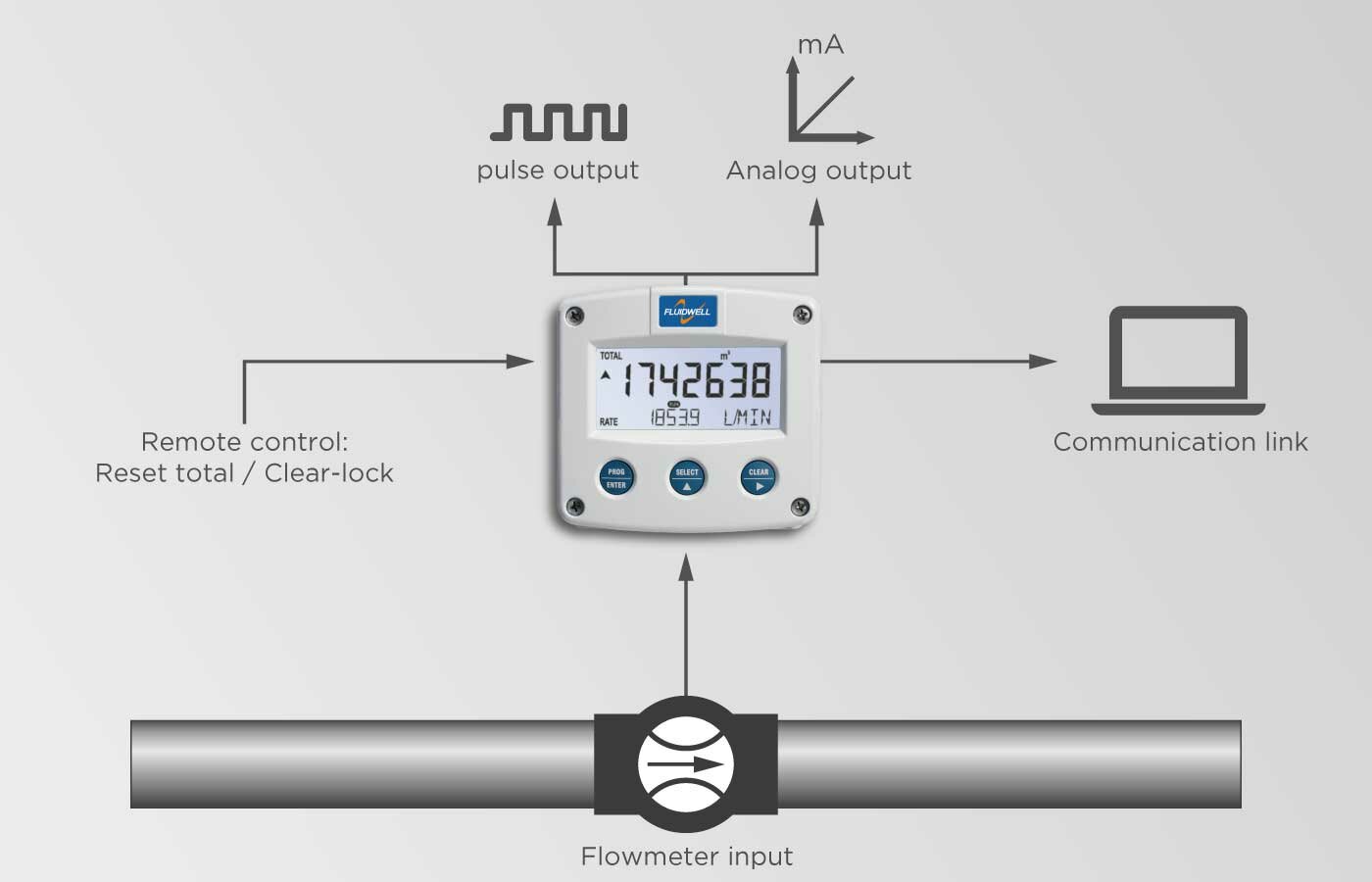

The Fluidwell F110 combines advanced measurement technology and ease of use to deliver reliable flow data and totals. With support for multiple types of signal inputs, it is compatible with a wide range of flowmeters, making it a versatile solution for both continuous monitoring and batch applications.

The durable enclosure protects the device in challenging environments, and the clear display makes it easy to monitor data even in low light conditions. The product is used in a wide range of industries, from water management to energy and process industries.

Features and benefits

- Multiple signalling inputs: Compatible with pulse and analogue signals.

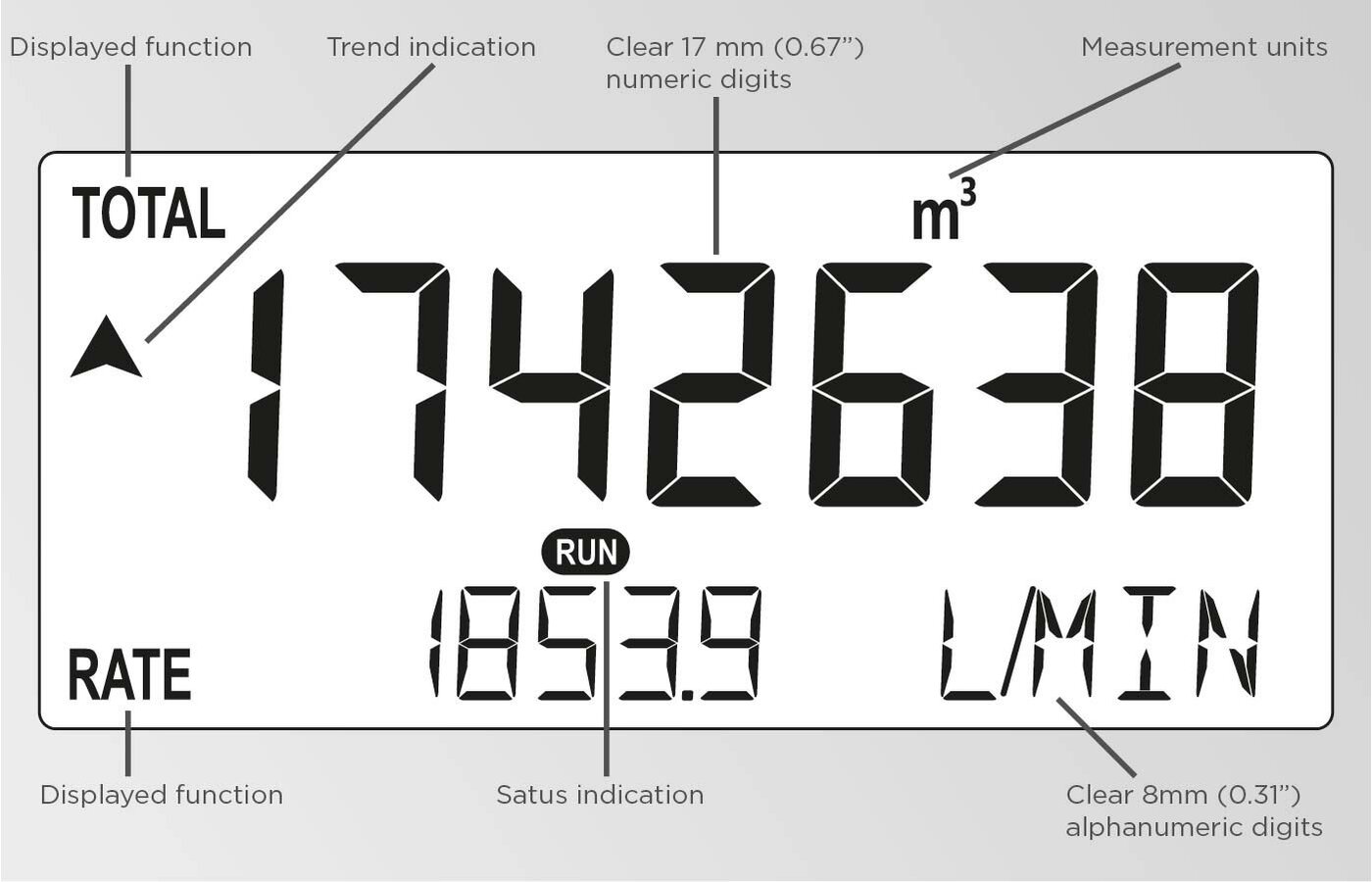

- Clear LCD display: Easy reading of flow data and total values.

- Flexible power supply: Battery, AC and DC options.

- Robust construction: Withstands harsh industrial environments and extreme temperatures.

- Certifications: ATEX and IECEx certified for potentially explosive atmospheres.

Applications

- Water management: Monitoring of fluid flows.

- Energy management: Totalisation of flows for optimised operations.

- Process industries: Accurate measurement and monitoring of liquids and gases.

- Batch applications: Control and measurement of partial flows.

| Property | Specification |

|---|---|

| Signal Inputs | Flow meter inputs: Reed switch, open collector, NAMUR, NPN/PNP pulse, sine wave (coil), active pulse signal. Analogue signals: 4-20mA. Status inputs: External reset to clear total value or disable manual reset via keypad. |

| Signal Outputs | Pulse outputs: Function: Scaled pulse output according to accumulated total value (e.g. one pulse every 3.25 gallons). Max. frequency: 500 Hz. Adjustable pulse duration: 0.001-9.999 seconds. Type: A passive NPN transistor, active PNP transistor or isolated electromechanical relay.Alarm outputs: None. Analogue outputs: |

| Power supply | Power supply: Long-life lithium battery. Loop powered 4-20mA. 8-24V AC/DC. 115-230V AC. Basic: 8-30V DC.Sensor voltage: 3.2V, 8.2V, 12V or 24V DC. |

| Hazardous Area | Intrinsically safe: ATEX: Gas: II 1 G Ex ia IIB/IIC T4 Ga Dust particles: II 1 D Ex ia IIIC T200 100 °C Da IECEx: Gas: Ex ia IIC/IIB T4 Ga Dust particles: Ex ia IIIC T200 100 °C DaExplosion Proof: ATEX/IECEx: Gas: II 2 G Ex db IIB+H2 T5 Gb Dust particles: II 2 D Ex tb IIIC T80°C Db. |

| Communication | Function: All process data and settings can be read and modified via the communication link. Protocol: Modbus ASCII / RTU. Interfaces: RS232 / RS485 2-wire or 4-wire / TTL. HART communication: Available with F018 flow monitor / totaliser. |