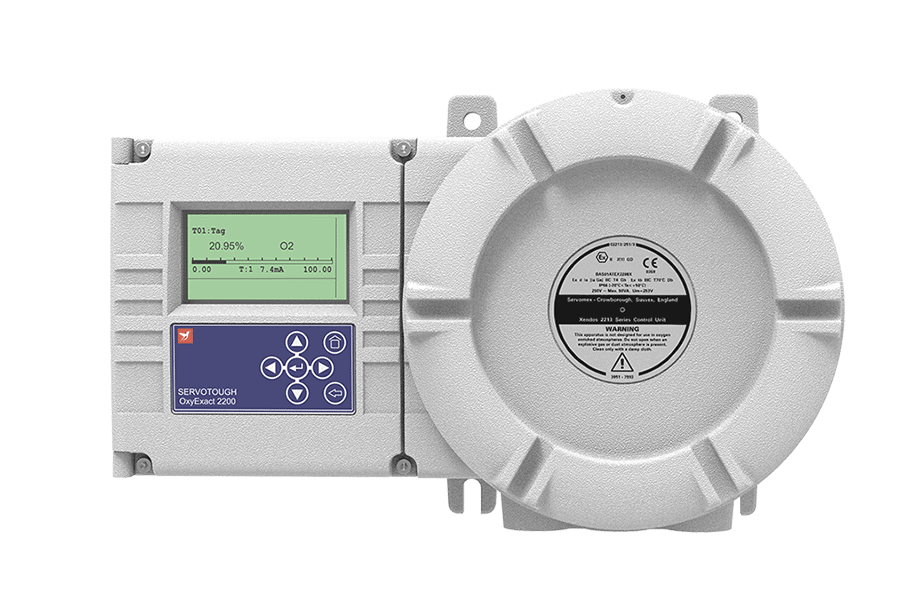

The OxyExact 2200 is designed to meet the most demanding applications in process monitoring and safety control. It utilises advanced paramagnetic technology to deliver stable and accurate oxygen measurements, which are essential for processes that require high precision.

One of the unique features of the OxyExact 2200 is its modular design, consisting of one control unit and up to six transmitters. This allows for flexible installation and easy integration into different process environments. The control unit can be placed in both safe and hazardous areas, providing further customisability depending on the application requirements.

Varieties and their unique characteristics

OxyExact 2200 is available in several variants to suit specific application needs:

- 2210 SV01: A user-configured model that is pre-set to meet basic requirements in most hazardous area applications.

- 2213 SV01: Similar to 2210 SV01 but with an intrinsically safe section to protect the screen and keypad, making it suitable for more demanding environments.

- 2222H SV01 and SV02High temperature transmitters for applications requiring the handling of high dew point gases. These models are pre-configured to meet medium level requirements in process measurements.

- 2223 SV01, SV02 and SV03: Standard transmitter for general oxygen measurement needs, with different configurations to suit specific applications.

Each variant is designed to offer optimal performance and safety depending on the specific requirements of the application. The modular design allows for easy upgrading and maintenance, minimising downtime and increasing system reliability.

Features and benefits

- High accuracy: Uses paramagnetic technology for stable and accurate oxygen measurements.

- Flexible design: Modular system with control unit and up to six transmitters for customisable installation.

- Security and safetyCertified for use in hazardous areas, including Zone 1 and Division 1.

- User-friendly: Intuitive interface and easy integration into existing systems.

- Low maintenance cost: Non-consuming sensor and robust design minimise the need for regular maintenance.

Applications

- Process monitoring: Ideal for monitoring oxygen levels in various industrial processes.

- Security check: Used to ensure safe oxygen levels in hazardous environments.

- Quality control: Helps maintain product quality by closely monitoring oxygen concentrations.