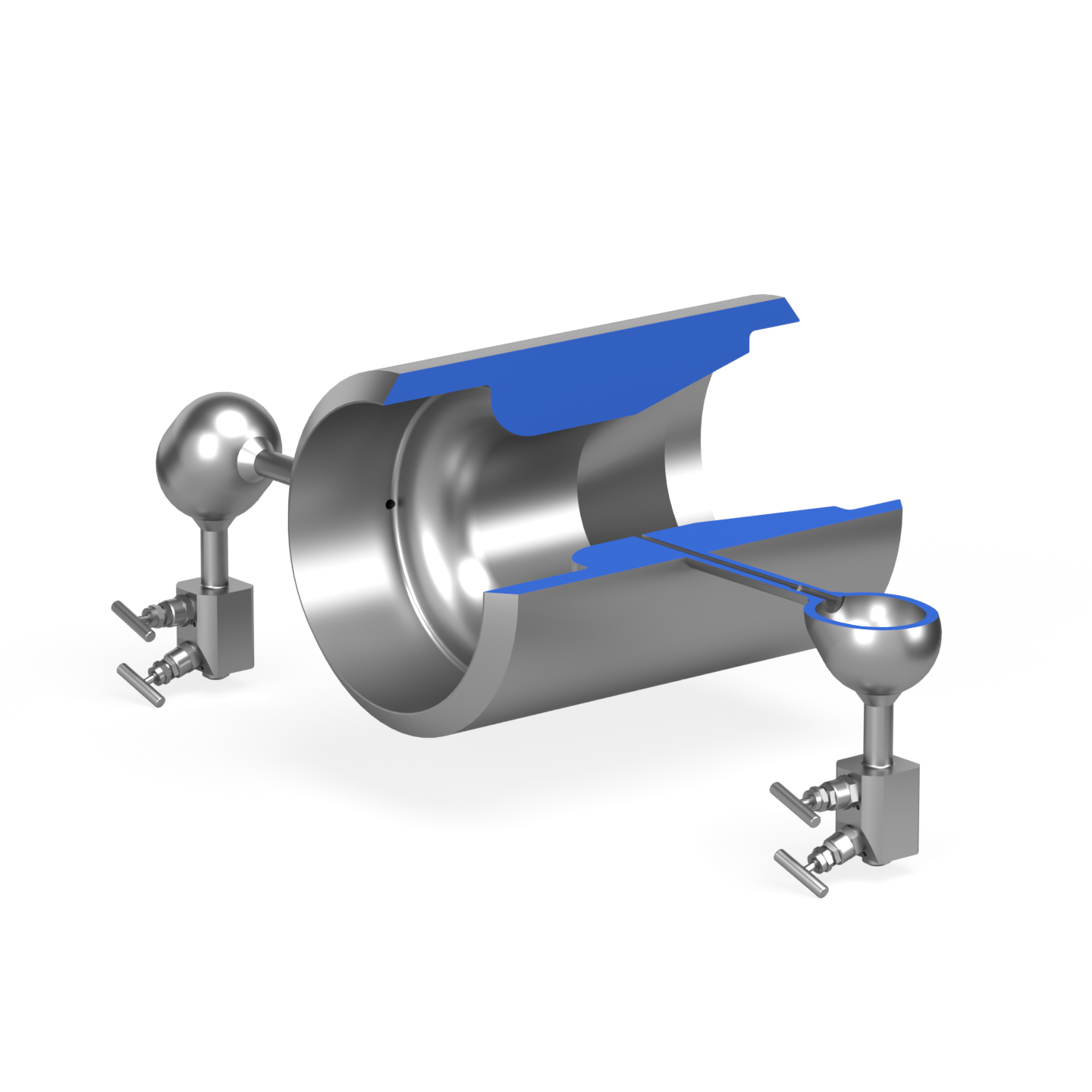

The design and construction of a Venturi nozzle is based on Bernoulli's principle and is very stable at high temperatures and flow rates. The Venturi effect is named after the 18th century Italian physicist Giovanni Battista Venturi, who discovered the phenomenon. The function is based on the differential pressure principle and is designed according to the ISO 5167-3 standard.

The venturi nozzle is available with weld ends or flanged process connections, depending on customer applications and requirements. Made of solid steel, the venturi nozzle is well suited for high pressure steam boiler applications and is often installed in the main steam line between the boiler and the steam turbine. It provides accurate flow measurement and causes less permanent pressure loss compared to the ISA1932 flow nozzle.

Characteristics:

- Used for flow measurement of vapour, liquid, air, water, steam and gas

- Very accurate when measuring flow rate

- Lowest pressure loss in the family of primary flow elements